Several analyst reports expect that the direct market for AM (Additive Manufacturing/3D-Printing) will grow to at least $20 billion by 2020—a figure that represents just a fraction of the entire tooling market today. However, we believe that the overall economic impact created by AM could be much higher, reaching $100 billion to 250 billion by 2025, if adoption across industries continues at today’s rate. Most of that potential will come from the Aerospace and Defense, Automotive, Medical, and Consumer-goods industries.

As per the present scenario many software's for STL file repairing are available as i have

discussed in my previous article:

discussed in my previous article:

In this article I will discuss about STL file repairing with the help of Materialise Magics software and focus upon important fixing operations available in it. Throughout this article I will be using Magics version 18.03 which can be easily accessed and downloaded through Internet.

Materialise Magics RP is a powerful software use to repair 3D files or .STL files for 3D-Printing. Magics bridges the gap between CAD and AM machines by importing nearly all standard CAD formats. I will be using Magics

version 18.03 in

this study.

Whether

you are using Traditional CAD or Other packages such as Google SketchUp, PTC CREO, SolidWorks or Rhino, Magics provides us numerous import options:

1. Manage the resolution of our data while importing (for better STL quality).

1. Manage the resolution of our data while importing (for better STL quality).

2. Import native color information.

3. Fix files automatically during import.

Tip: Working

with large

files

can cause Magics to crash. Save often, and save incrementally so that you can go back to an older version

of your file if need be.

Magics Workflow: Use the Fix

Wizard tool to

repair .STL file before submitting it for

3D

printing. The Fix Wizard

tool will guide you through the essential steps to fix a

corrupt STL file.

1. To

bring in your file, go to File

>

Import

Part

2. To start the Fix Wizard, go to Fixing > Fix Wizard

3. Magics will ask about

if you want to change the memory state of

the part: say Yes.

4. The Fix Wizard should load with the Diagnostics page highlighted. If not, click Diagnostics from the left menu.

5. To

run Diagnostics on your

file, click Update.

A green check (V) means

there are no

issues of that kind. Red cross (X) denote

specific

issues

with your file. Your mesh must have green check

marks in all fields

except Triangles

and Overlaps when

you submit your file for 3D printing.

Triangles and Overlaps must

be less than 300 each.

If your file has all green check marks and

less than 300 Overlaps or Triangles, we

are ready to Submit.

Common .STL file Error types explained.

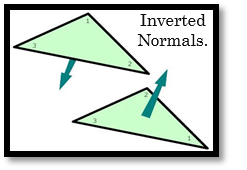

1. Inverted Normals: In the STL

format, a normal indicates the outside of a triangle. When the normal points to

the wrong direction (the

inside), the triangle needs to be

inverted to have a watertight STL. This triangle is then called

a flipped triangle.

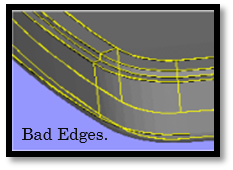

2. Bad edges: To have a

correct STL file, all edges of each triangle should be connected properly to a neighbor. If an edge is

not connected properly, the edge is called a bad edge and is indicated with a yellow line.

3. Bad contours: A group of bad

edges connected to each other form a bad contour.

a. Near bad edges: Near bad edges

are bad edges that are near other bad edges. These are mainly caused by 2 surfaces that are not

well connected.

4. Intersecting triangles: Intersecting triangles are triangles

cutting each other. It can happen sometimes that the STL surface has intersections.

5. Overlapping Triangles: An STL-file

sometimes has overlapping triangles. These triangles can be removed with the tools in the double

surfaces page. 2 triangles are considered as overlapping as:

a. The distance between them is smaller than the

given tolerance. (E.g. 0,1 mm

or 0,005 inch).

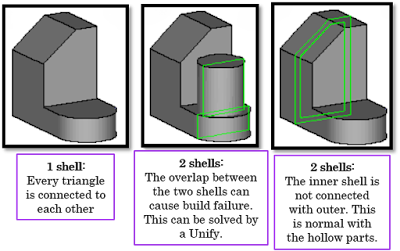

6. Shells: A shell is a collection of triangles

connected to each other. Normally a part has only one shell because every triangle of the part is

(indirectly) connected to every other triangle.

:

7. Noise shells: Some shells

have no geometrical meaning and are considered as noise (waste) that we can throw away. However,

it is recommended to look at these shells first before removing them.

a. Conditional: Magics will only fill a contour when he recognizes it as a hole. Some contours aren’t holes.

Manual Fixing:

STL file fixing in detail.

Diagnostics (Advised way of working):

1. Use the check boxes to indicate what to analyze.

2. The result of the analysis is shown in bold,

the V or X indicates

if it's ok or not.

3. The features you can analyze. Click on the

link for an explanation of what they are.

4. To analyze the checked items.

5. This is the advise, based on the analyzed data.

6. This button will automatically apply the

advised fixing operation.

.

Tips and tricks:

Change the advice

You can influence the advice with the check boxes. When unselecting

a checkbox, the advice will not

take this parameter in account. When Magics keeps on sending you to a certain

fixing step, you can

skip it this way.

A full analysis is giving you the best result but

consider that:

a. Each analysis takes

time (especially the overlapping triangles and intersecting triangles)

b. In the beginning you often do not need all information (especially the overlapping triangles and

intersecting triangles).

c. Depending for what you're going to use your

STL-file afterwards, you may not need to repair

intersecting and

overlapping triangles.

Combined Fixing

(Advised way of working):

Automatic Fixing:

2. Magics will do a set of predefined actions.

3. Go back to the Diagnostics page to see the

results, by clicking on

Manual Fixing:

Here you can decide yourself what

actions you want in the combined fixing.

Fix Normals: Magics will

reorient the normal of the triangles automatically. An

STL may not contain any inverted (red) triangles to be

watertight (= printable).

Stitching: Two bad edges (yellow lines) which are close enough to each other

can stitched automatically by pulling the open edges towards

each other. This

way, you get a watertight STL.

Tolerance: Here you indicate what distance a point may be moved to fix the near

bad edge.

Iterations: To get better results, the stitching is done in iterations, starting

with a small tolerance

and ending with the given tolerance.

Fill holes:

a. Conditional: Magics will only fill a contour when he recognizes it as a hole. Some contours aren’t holes.

b. Type of hole filling:

Ø Planar: The hole will be filled as it is a

planar hole.

Ø Freeform: Complex shaped contours are better

filled as free-form holes.

Ø Grid: The triangle size of the surface

that is used to fill the contour.

Unify: This will remove all internal geometry and intersecting triangles. This

operation will only be

done if the geometry allows it.

Filter sharp triangles: Sharp triangles will be removed to

improve surface quality.

Click on the Fix button in order to

execute the defined manual fixing.

Normal Fixing (Advised

way of working):

Automatic Fixing:

2. Magics will do an automatic orientation of the normal.

3. Check if all triangles are oriented correctly.

4. The default color of the inside of a triangle

is red. If you still see red triangles, they can be triangles with inverted normal (or a hole).

5. If there are still triangles with inverted

normal, orient them correctly with the manual tools.

Manual Fixing:

Stitching (Advised

way of working):

Automatic Fixing:

Automatic Fixing:

2. Magics will estimate a stitching tolerance.

3. Magics will stitch iteratively using this tolerance.

4. Check if there are still near bad edges.

5. Do a manual stitching with a higher

tolerance if needed.

Manual Fixing:

a. Tolerance: Magics will

reposition points to make triangles of different

surfaces fit correctly.

b. Iterations: To avoid errors caused by high tolerances, Magics can stitch in iterations, starting

with a stitch with a very small tolerance

and ending with the given tolerance.

Noise Shells Fixing (Advised

way of working):

Some

shells have no geometrical meaning and are considered as noise (waste) that we can throw away.

However, it is recommended to look at

these shells first before removing them.

Even

a shell of a few triangles can be

important.

Automatic Fixing:

2. If you're not sure you can remove

the noise shells manually.

3. The shells shown in a list sorted by amount

of triangles.

6. If the visible shells do not

represent important geometry, you can remove them.

9. It can be that there are other noise shells

present.

Manual Fixing:

Holes Fixing (Advised

way of working):

How to recognize a hole?

Automatic Fixing:

2. Magics will fill all the planar holes.

a. Non planar holes will not be filled.

b. Planar holes will not be filled if the

"new" triangles would intersect existing triangles.

3. Check the part.

4. The new triangles (used to fill the holes)

are marked.

5. Check if there are still holes left (non

planar holes will not be filled automatically).

6. Use the manual tools to fill the holes that

are still left.

Manual Fixing:

First

you’ll need to identify what kind of hole you're dealing with:

Overlaps Fixing

(Advised way of working):

Automatic Fixing:

2. Your piece needs to have less than

300 Overlaps for submission in the 3D Printing Center.

3. If you cannot achieve this with

Automatic Fixing, you will need to manually fix the errors.

Shells Fixing (Advised

way of working):

It

can happen that your part consists of multiple shells. Use this tool to

manipulate the

shells. Because

this is not really an error, there's no

automatic way to solve this

problem.

Automatic Fixing:

Automatic Fixing:

a) Shell

list

b) Manual

If the Automatic

Fix does not get rid of extra

shells or combine

your shells into one, you can use the Manual Fix to do these operations. First, you must determine why there

are extra

shells. Go into the Shells tab in the Fix

Wizard, then extend the window down so

you can see more of the shells listed.

Click on a shell in the dialog

box, and Magics will highlight in green. Click on each individual shell

to see which piece of your object it is. You will be able to determine if the

individual shells are pieces you need to keep or if they can be deleted. If

they can be deleted, select the ones you would like to delete, and click Deleted

Selected Shells.

Tip

1: Hold

SHIFT and click to select multiple

shells for deletion.

Tip 2: Keep an eye on the triangle count of

your shells. Shells at the top of the list have many triangles, and these are likely to be the main

pieces of our object. Shells with very few triangles, at the bottom

of the

list, could be extra geometry that we don’t need.

After

deleting unnecessary

shells, click Update to see if the problem has been fixed. If not, use the Automatic Fix on the

Shells page, and Update again. Return to the

Diagnostics

page and Update to see the new status of your piece.

No comments:

Post a Comment